ASTM E1354

Cone Calorimeter TESTING

REQUEST A QUOTE

ASTM E1354 Cone Calorimetry Testing

Small Specimens, Large Amounts of Data

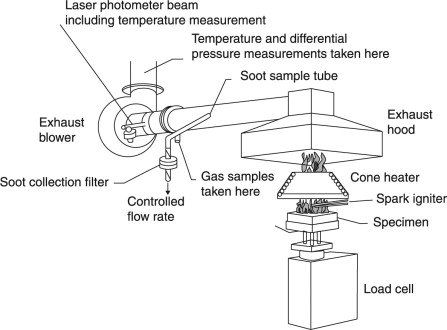

The Cone Calorimeter

How is ASTM E1354 testing performed?

ASTM E1354 test specimens are 3.94 x 3.94 inches (100mm x 100mm) with a maximum allowable thickness of 2 inches (50mm). Test specimens should be representative of the end-use construction and flat whenever possible. Prior to testing, specimens are conditioned to constant weight in an environment that is 73 °F (23 °C) and 50% relative humidity. Specimens are wrapped around the backside and edges with aluminum foil and held in a metal sample holder for testing.

Before the test begins, daily calibrations are performed on the equipment. The furnace can be set to a heat flux between 0 and 100 kW/m², but it is most commonly set at 35 kW/m² or 50 kW/m². A specified and consistent exhaust airflow is established and the baseline oxygen concentration readings are taken.

To begin the ASTM E1354 test, the test specimen is placed on top of the load cell and underneath the conical shaped furnace. A spark ignitor is moved overtop the sample surface until sustained burning is achieved across the entire sample surface. The test can also be conducted without the use of the spark ignitor. The products of combustion are pulled through the exhaust system where a laser is passed through the duct to measure smoke and gas is sampled and sent to the oxygen analyzer. The test is continued until two minutes after one of the following: the last sign of flaming, the mass loss rate drops below 150 g/m², the specimen mass has been completely consumed, the oxygen concentration returns to pretest values, or 60 minutes have elapsed. The test can also be stopped if the specimen has not ignited after 30 minutes from the start of the test and no signs of heat evolution are seen.

What data will be included in an ASTM E1354 report?

- Time to Ignition

- Time of Flame Out (where applicable)

- Peak Rate of Heat Release

- Time to Peak Rate of Heat Release

- Average Rate of Heat Release (60, 180, 300 seconds)

- Total Heat Released

- Average Effective Heat of Combustion

- Initial and Final Mass

- Mass Loss Rate

- Average Smoke Extinction Area

- Time to Peak Smoke Extinction Area

When is cone calorimeter testing needed?

The ASTM E1354 test method has been developed for evaluating materials, conducting research and development, computer modeling, design, and to assist in making real world fire predictions. The cone calorimeter is also used as an alternate test method when a material cannot be properly tested using commonly cited methods due to the materials inherent properties (e.g. melting materials tested in accordance with ASTM E162).

Is Capital Testing an accredited ASTM E1354 laboratory?

Capital Testing and Certification Services is ISO/IEC 17025 accredited to conduct ASTM E1354 testing. ISO 5660-1 (a common alternate) is also covered under Capital Testing's scope of accreditation. Click Here for Capital Testing's full ISO/IEC 17025 scope.

Contact chrisp@capitaltesting.org for more information about ASTM E1354 or ISO 5660-1 testing.

HAVE ANY QUESTIONS?

Contact Us footer form

We will get back to you as soon as possible.

Please try again later.

© Capital Testing | All rights reserved