Small-Scale

Flammability Testing

Benchtop Methods

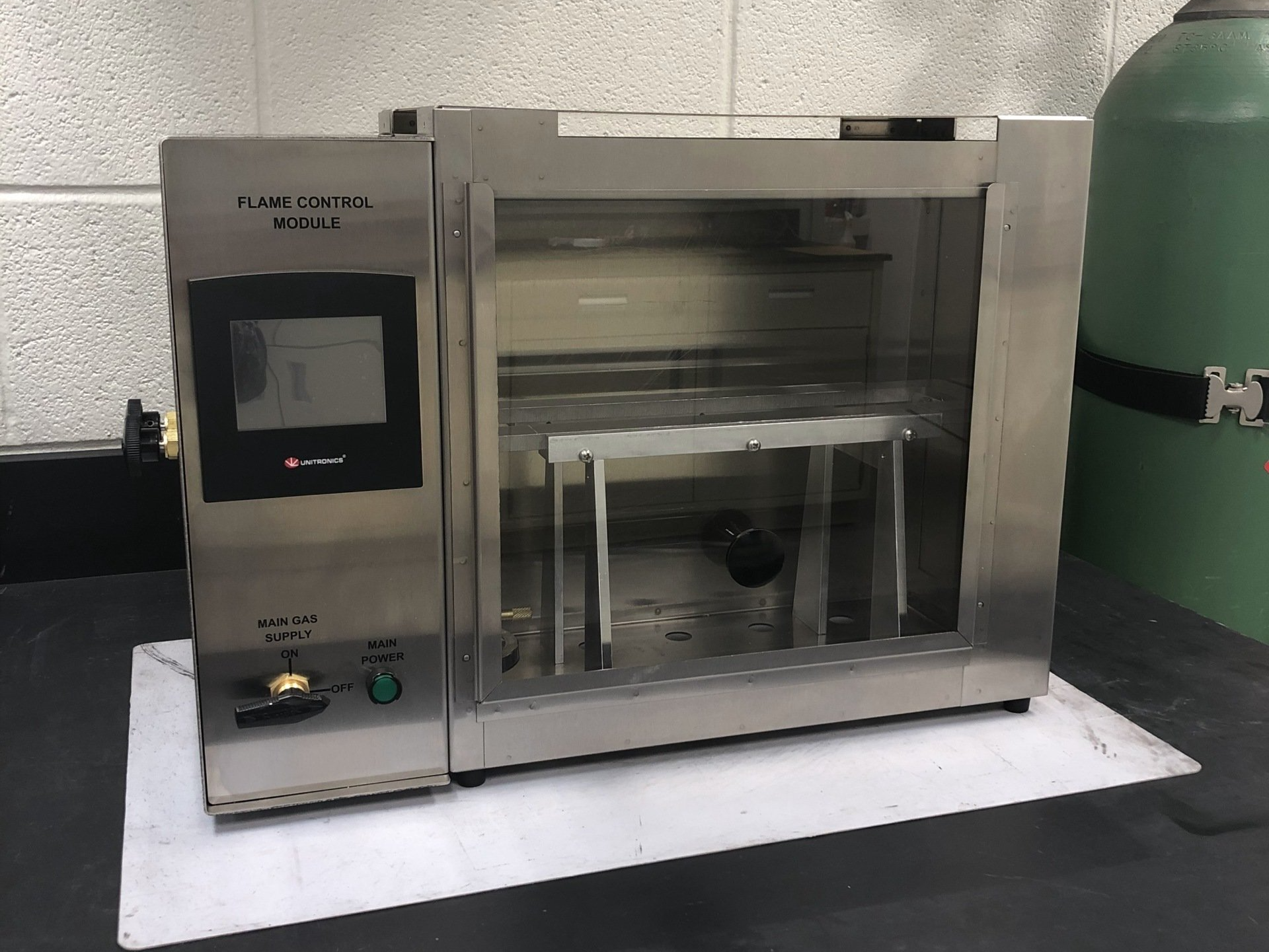

Small Scale Fire Laboratory - Flammability Testing

Flammability Testing for Aerospace, Automobiles, and Other Materials used in Mass Transit

- ASTM C1166 - Flame Propagation of Dense and Cellular Elastomeric Gaskets and Accessories

- ASTM D6413 - Flame Resistance of Textiles - Vertical Test

- FMVSS 302 / CMVSS 302 / 49 CFR 571.302 - Flammability of Interior Materials (Automobiles)

- FAR 25.853 / 14 CFR 25.853 /14 CFR Part 25, Appendix F, Part I - Flammability of Compartment Interiors (Aerospace) - Horizontal and Vertical

ASTM C1166 - Flame Propagation of Dense and Cellular Elastomeric Gaskets and Accessories

The ASTM C1166 test method covers a laboratory procedure for determining flame propagation characteristics of a dense or cellular elastomeric gasket or an accessory when exposed to heat and flame, with no significance being attached to such matters as fuel contribution, rate of flame spread, smoke developed, or the nature and temperature of the products of combustion.

Specimen Requirements: Specimens shall be ½ inch thick by 1 inch wide by 18 inches long. When the finished product cannot be tested due to size, shape or dissimilar materials, standard test strips shall be prepared. Specimens shall be free of permanent set (curvature), abnormally porous sections, and foreign materials. All specimens shall be made from the same compound, same dated batch and shall have the same density and state of cure. Capital Testing only provides ASTM C1166 testing services. It is up to the client to provide specimens that meet the standard requirements. Six specimens must be tested.

Summary: The test specimen’s length is measured and then the test specimen is hung vertically. The specimen is held with a clamp that is positioned at the top of the specimen. Two wire loops are used to keep the specimen over top of the flame throughout the test.

A burner with a 1.5” tall blue flame is placed directly underneath the bottom of the test specimen. The sample is positioned so that the inner cone of the flame touches the lowest part of the specimen. Cellular material is exposed to the flame for 5 minutes and dense material is exposed to the flame for 15 minutes.

After the burner flame is extinguished, the specimen is permitted to burn until it no longer propagates flame. Once the flaming has ceased, the specimen is quenched in water and then loose char is removed with a stiff brush. The remaining unburned length is then measured. If the unburned length is uneven, then two measurements may be taken.

Performance Criteria: ASTM C1166 does not establish specific performance criteria. The most commonly used performance criteria can be found in the National Fire Protection Association publication NFPA 130 (Standard for Fixed Guideway Transit and Passenger Rail Systems) and 49 CFR Part 238 (Passenger Equipment Safety Standards). The material passes if the Average Flame Propagation (FP) ≤ 100mm (4in.). The material shall also not exhibit any flaming running or flaming dripping

ASTM D6413 / ASTM D6413M

Flame Resistance of Textiles (Vertical Test)

This test method determines the response of textiles to a standard ignition source, deriving measurement values for afterflame time, afterglow time, and char length. ASTM D6413 has been adopted from Federal Test Standard No. 191A method 5903.1.

Specimen Requirements: Cut five lengthwise and five widthwise test specimens 76 mm [3.0 in.] by 300 mm [12 in.]. For woven fabrics, the long dimensions are cut parallel to the warp yarns for lengthwise tests and parallel to the filling yarns for widthwise tests. Take lengthwise specimens from different positions across the width of the fabric. Consider the long direction as the direction of the test. Label to maintain specimen identity.

Summary: A specimen is positioned vertically above a controlled flame and exposed for 12 seconds. The flame is then removed, and afterflame time and afterglow time are measured. Char length is measured under a specified force. Any evidence of melting or dripping is noted.

FMVSS 302 / CMVSS 302 / 49 CFR 571.302 Horizontal Flammability of Interior Materials (Automobiles)

Federal Motor Vehicle Safety Standard No. 302 (FMVSS 302) and Canadian Motor Vehicle Safety Standard No. 302 (CMVSS 302) specify the burn resistance requirements for materials used in the occupant compartments of motor vehicles.

Specimen Requirements: Each specimen shall be a rectangle 102 mm wide by 356 mm long, wherever possible. The thickness of the specimen is that of the single or composite material used in the vehicle, except that if the material’s thickness exceeds 13 mm, the specimen is cut down to that thickness measured from the surface of the specimen closest to the occupant compartment air space.

Summary: Specimens are mounted horizontally in a U-shaped frame with an interior exposed area of 51 mm x 330 mm (2 in. x 13 in.). The surface of the specimen that would typically be closest to the occupant compartment airspace faces downward in the test frame. A Bunsen burner with a 38 mm (1.5 in.) flame is positioned so that the center of the burner tip is 19 mm (0.75 in.) below the center of the open edge of the test specimen. The specimen is exposed to the burner flame for 15 seconds. Timing begins (without reference to the time of burner flame application) when the flame front reaches a point 38 mm (1.5 in.) from the open end of the specimen. The time is recorded until the flame front reaches the clamped end of the specimen. If the flame front does not reach the clamped end of the specimen, then time is recorded until the point where flaming stops.

Performance Criteria: The material or composite shall not burn, nor transmit a flame front across its surface, at a rate of more than 102 mm per minute. If a material stops burning before it has burned for 60 seconds from the start of timing, and has not burned more than 51 mm from the point where the timing was started, it shall be considered to meet the burn-rate requirement.

FAR 25.853 / 14 CFR Part 25, Appendix F, Part I

Flammability of Compartment Interiors (Aircraft) - Horizontal and Vertical

Capital Testing offers horizontal and vertical flammability testing for materials that will be used in aerospace applications as outlined in 14 CFR Part 25, Appendix F, Part I and the FAA Aircraft Materials Fire Test Handbook Chapters 1 and 3.

Specimen Requirements: Specimens tested will be either cut from a fabricated part as installed in the aircraft or cut from a section simulating a fabricated part. The specimen may be cut from any location in the fabricated part. However, the edge to which the burner is applied must not consist of the finished or protected edge of the specimen. Fabricated units, such as sandwich panels, will not be separated into individual component layers for testing. The specimens will be a rectangle at least 3 by 12 inches (75 by 305 mm), unless the actual size used in the aircraft is smaller. Directional materials should be tested in both directions.

Performance Criteria:

Horizontal - The average burn rate for all the specimens tested will not exceed 2.5 inches/minute for FAR 25.853(b-2) or 4 inches/minute for FAR 25.853(b-3), per Code of Federal Regulations (CFR), Title 14, January 1, 1990.

Vertical - The average flame time for all of the specimens tested will not exceed 15 seconds for either the 12-second or the 60-second vertical test. The average drip extinguishing time for all of the specimens tested will not exceed 3 seconds for the 60-second vertical test or 5 seconds for the 12-second vertical test. The average burn length for all of the specimens tested will not exceed 6 inches (152 mm) for the 60-second vertical test or 8 inches (203 mm) for the 12-second vertical test.